The FINEST Project is structured into three sub-projects, in which the actual research activities are conducted by the involved principal investigators and postgraduate students. The FINEST Research School is intended to open the perspective of the PhD students from their very specific topic to further aspects relevant for sustainable resource managers of the future. The research is supported by the FINEST Backbone being responsible for all coordination activities, while the FINEST Transfer Desk helps in all activities relating to the transfer of the results.

The structure of the FINEST project

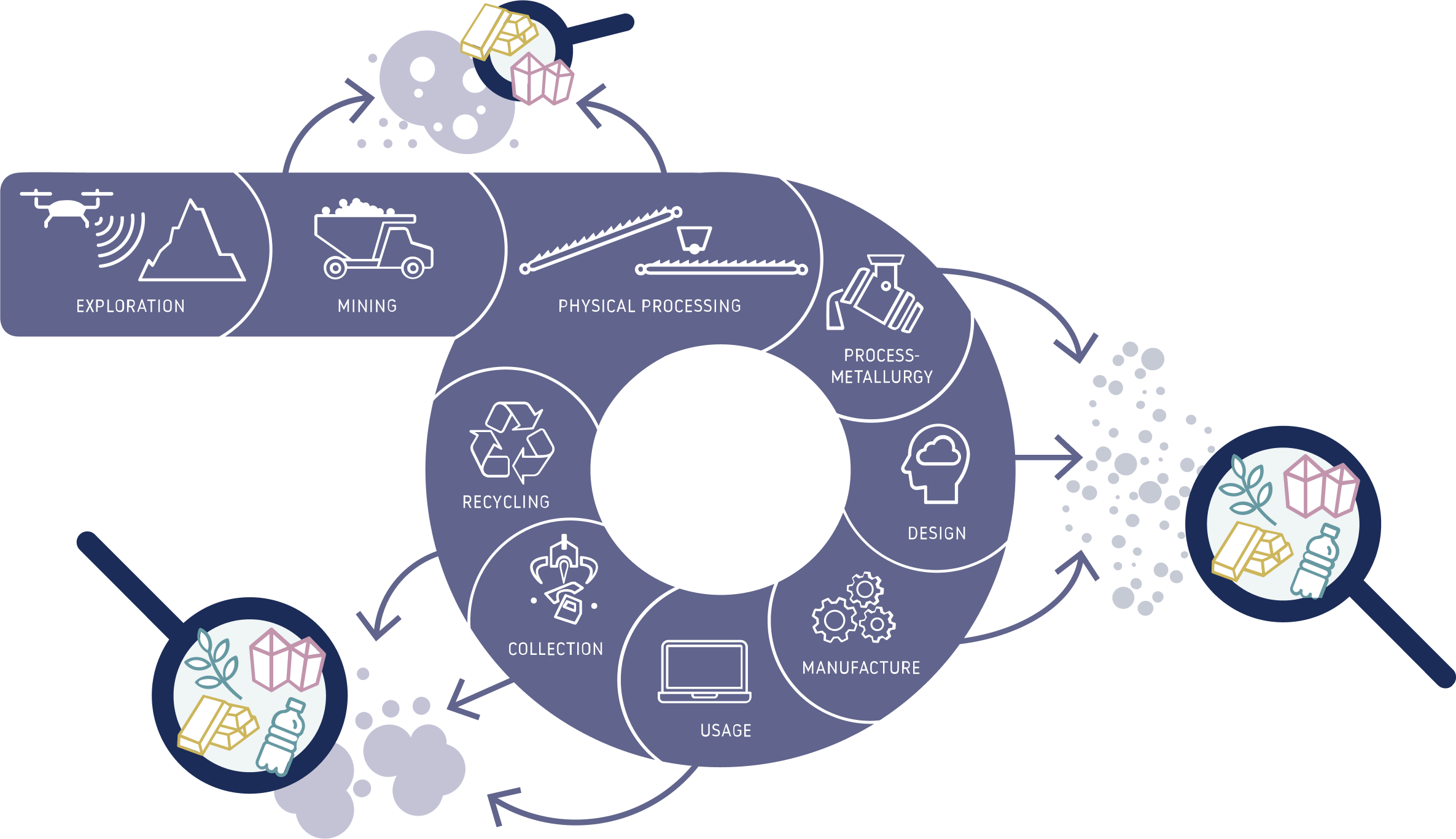

FINEST particulate anthropogenic material flows in a sustainable economy.

FINEST particulates dominantly remain untreated in current concepts of circular economy. Prominent examples named in the subprojects are microplastic, shredder dust, flue dust from smelters and inorganic fillers in plastics.

The FINEST Project examines physical properties of the waste and will suggest beneficial ways of blending. This approach allows unforeseen material designs from waste and waste management concepts. Disposal service providers, pyro-metallurgical industry partners and partners from inorganic industry play a decisive role in identifying and providing required materials.

The same partners will be involved in assessing the legal and economic framework for beneficial bulk processing attempts and blending concepts.

Possible use cases are manifold in industrial value chains. The following example focuses on the recycling of fine particulates from shredding of end-of-life electronic consumer goods or cars. Microbial recycling of the thermoset plastic particulates from the shredder may find a new usage as cycling helmets.

Thermochemical recycling of mixed residues of organic materials could maintain their chemical energy as feedstock for the chemical industry. Microplastic from the natural environment may be decomposed into biomass.

These simple examples illustrate the ecological and economical potential vested in fine-grained particulate materials. Well-beyond these simple examples, novel blending of these different material streams may provide unexpected synergies and significant contributions towards a sustainable circular economy.

Satellites Update

The HGF has decided to choose two out of three proposals from the FINEST consortium to enter stage 2 of the application process.